Auto or Manual

ROBOFORM adds instant flexibility to your shop floor. The unique sliding base allows you to use the press brake with or without automation. Run parts that with an operator during the day and run mid-to large- volume jobs at night.

The robot, mounted onto a solid base plate, is configured with added features that allow unmanned fabrication either lights on or lights out. The goal is to supplement your production with consistency and free up talent within the shop to take on different projects.

Load and Walk Away

Dual inbound tables provide blank capacity for hours of automated production. Prior to the first bend of each part, the robot presents the blank to a built-in double blank detector to confirm a single piece was picked from the inbound stack. This provides the assurance needed to run unattended.

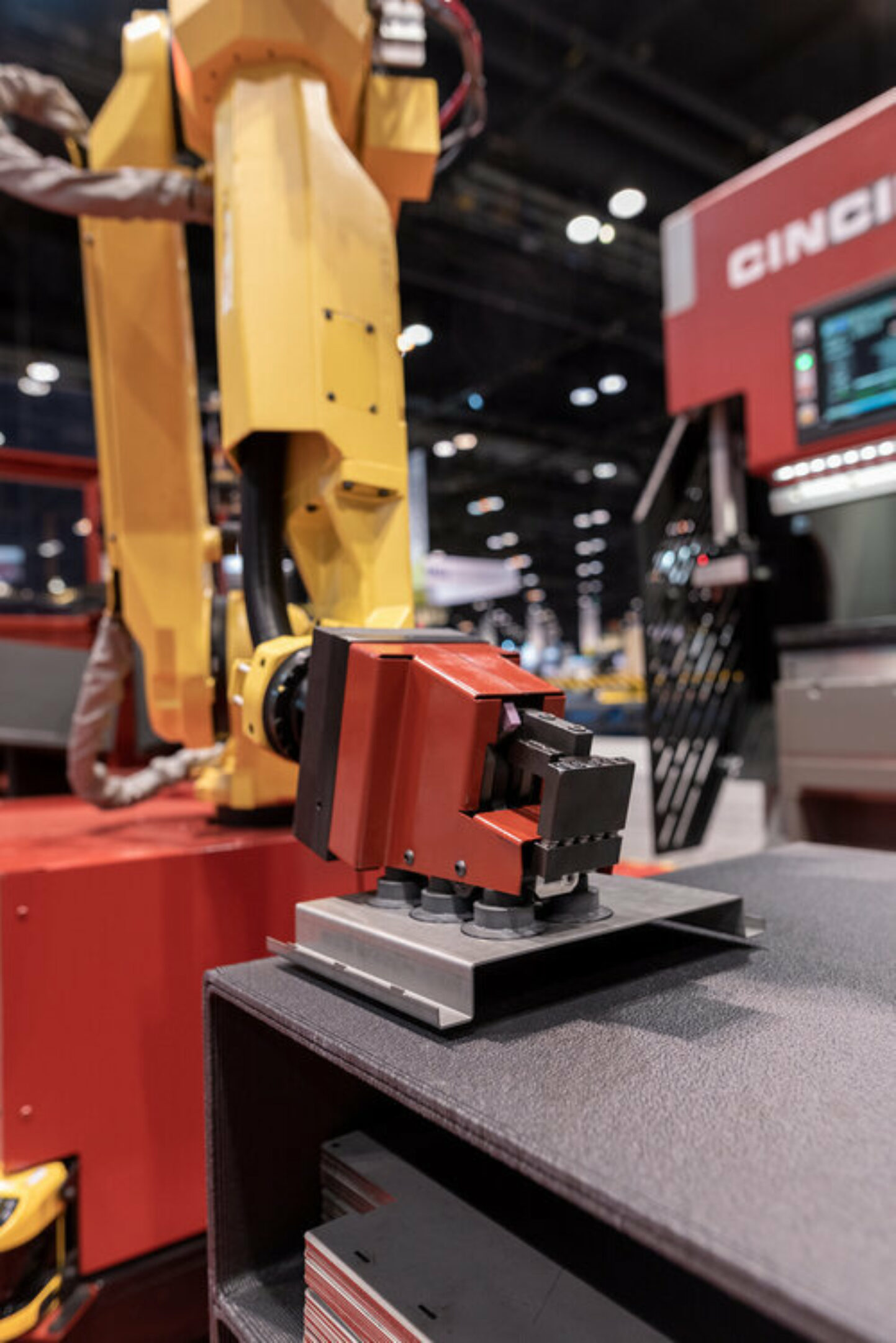

Multiple Grip Options

The ROBOFORM’s standard gripper allows parts to be handled with a mechanical clamp or pneumatic suction cups. The part handling method is selected as needed for each bend. As parts continuously change after each bend, the versatile dual gripper system allows parts to be held at various locations. For example, with one bend, the mechanical clamp will be programmed to hold the side of the part. For a second bend, the pneumatic suction cups might be selected to hold the bottom of the sheet metal. As the part takes shape during forming, a part regrip may be necessary to avoid part interference between the gripper and the robot arm, press brake or tooling. This can be programmed ahead of time to take place automatically.

Post-Bend Options

With the ROBOFORM, flexibility continues after forming is completed. Finished parts can be stacked on a table, a pallet, the floor or deposited into a container.

Built-in Safety Features

Without physical barriers, operators have easy access to the ROBOFORM and press brake. The work area is guarded by three optical scanners. When a person enters the perimeter of the work zone the robot slows down. If the person backs away, the robot returns to normal speed. When a person advances into the programmed work zone, the robot stops and shuts down.

Backed by Cincinnati Inc.

Buy the ROBOFORM directly from people you know. Sales, application studies, installation and support are provided by CI professionals.

So, with efficiency, productivity, safety and ease of operation, what’s not to love? If you want to run more parts through your shop at a time when talented operators are hard to find, ROBOFORM is the right place to start. Click or call and get in on the benefits of automation today.