Press brake drive systems

When deciding to purchase a new press brake, there are many factors to consider. One important factor is selecting the type of machine drive system that will best suit your production requirements, purchasing budget and running costs.

Hydraulic Press Brakes

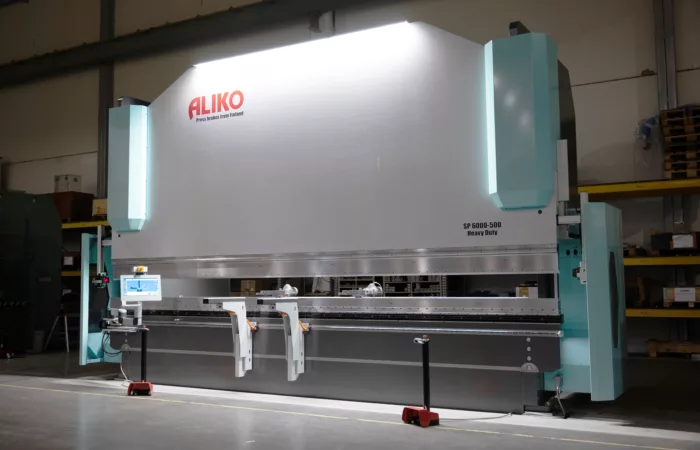

Standard hydraulic designs have been the primary type of drive system for press brakes for decades. While there have been more advanced hybrid and electric systems developed over the years, hydraulic press brakes still account for most machines manufactured today due to their reliability, versatility and flexibility. From small, light tonnage models right through to large machines with very high pressing force.

| Benefits | Typical Applications |

|---|---|

|

|

Explore the range of hydraulic models

-

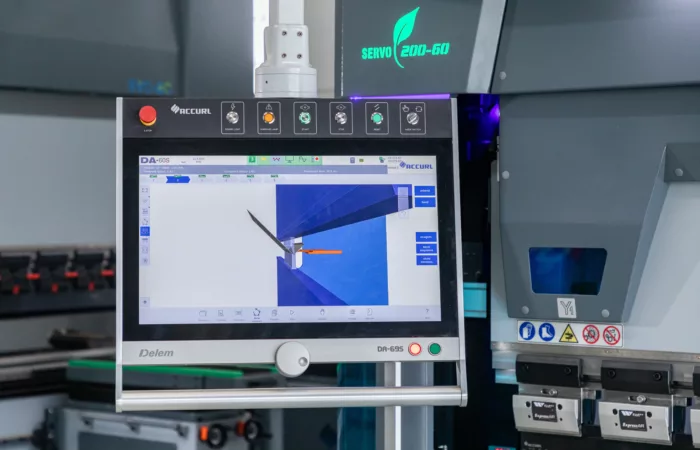

SYNCRO series

SYNCRO-series machines are a line of high-productivity hydraulic press brakes. Versatile and easy to use in both 2D and ...

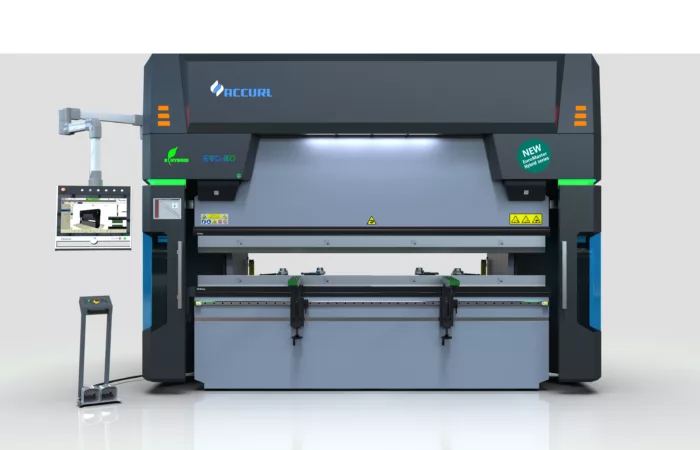

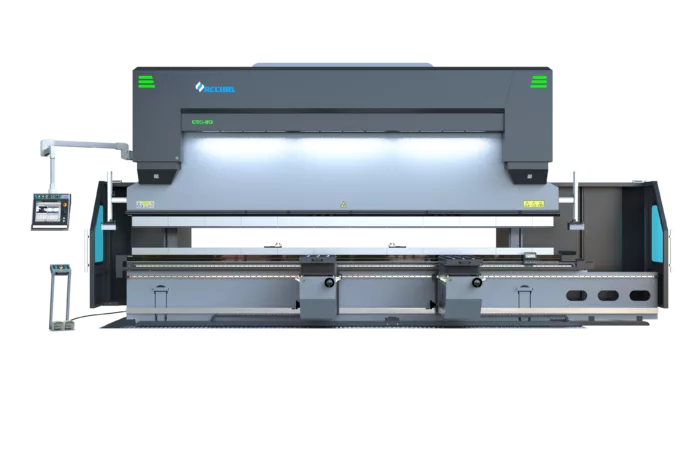

Hybrid Press Brakes

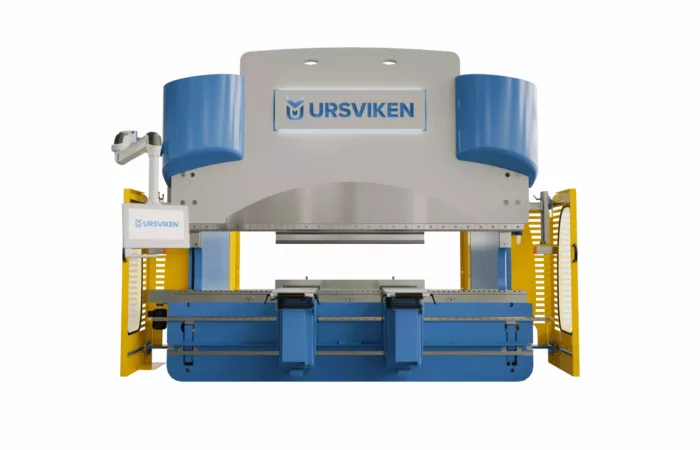

Hybrid press brakes combine both hydraulic and electric elements, achieving a more energy efficient drive system with improved performance.

Hybrid press brakes use a bi-directional servo electric drive system to pump oil to the hydraulic cylinders. Compared with a traditional hydraulic system where the pump is running continuously, even when the machine is idle, a hybrid system is only working when motion is required. This means that hybrid systems consume very little energy when idle and are more energy efficient when working.

Hybrid systems use a smaller hydraulic oil tank, leading to a more efficient design and lower maintenance costs when an oil change is required.

When it comes to noise output, hybrid systems are quieter than hydraulic machines due to the lower sound levels of the servo electric drives compared with traditional hydraulic pump motors and that they are only running while the machine is being operated.

| Benefits | Typical applications |

|---|---|

|

|

Explore the range of hybrid models

-

HSYNCRO series

The Axial line of HSYNCRO machines are hybrid press brakes. They feature reduced energy usage, oil capacity and lower no...

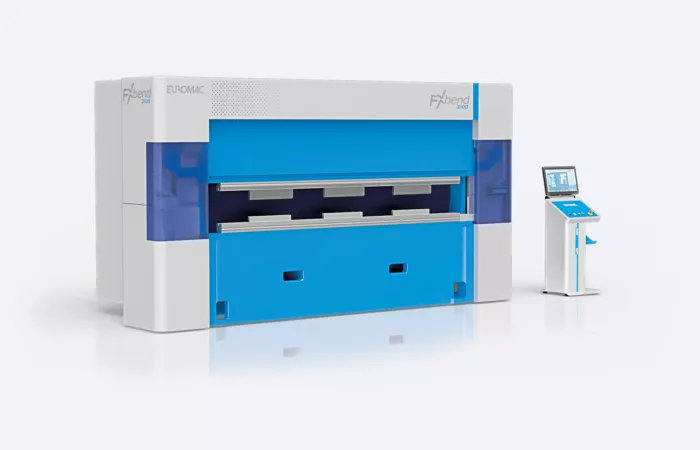

Electric Press Brakes

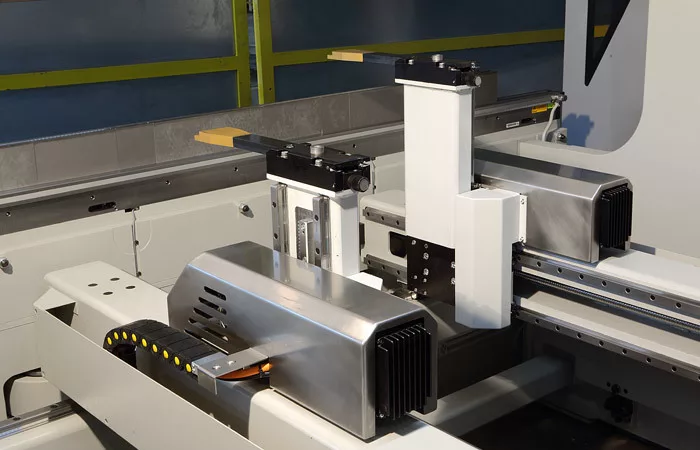

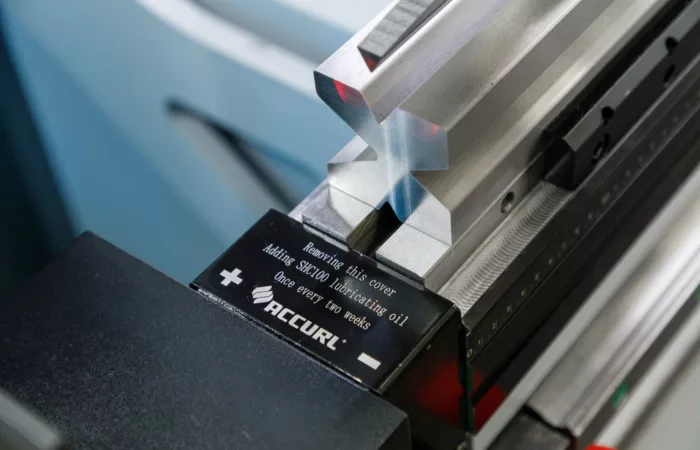

Electric press brakes eliminate the need for hydraulic pumps, valves and complex piping, for an extremely quiet, fast and efficient bending solution. Electric machines can feature a variety of drive methods including belt or gear direct drive systems and belt / pulley systems for even distribution of pressing force on longer machines.

Smaller models are ergonomically designed with integrated foot pedals and folding support tables that allow workers to comfortably operate the machine from a seated position as well as offering a range of additional features that help to reduce operator fatigue.

| Benefits | Typical applications |

|---|---|

|

|