ADVANCED CAPABILITY

The latest version of CADMAN is able to integrate foreign operations – defined as non-core and secondary operations, including tapping, deburring, and grinding. This update helps enhance the sheet metal fabrication process flow by allowing CADMAN to control, monitor and log an order from raw material to finished part. Foreign operations are now visible in the CADMAN-JOB overview screen, and can be tracked and traced in the production process for real-time transparency. Using a single system (CADMAN) keeps the user interface consistent and helps improve process efficiency.

CADMAN v8.7 also provides a real-time interface between ERP and sheet metal production. The ERP system transfers work orders to CADMAN-JOB for processing. In turn, CADMAN-JOB provides ERP with a real-time order status. The order’s progress in the production journey can be tracked in both systems. The data gathered can be analyzed by the user to implement process improvements.

SUITED FOR COMPANIES OF ALL SIZES

CADMAN v8.7 can now manage the complete sheet metal production process without the need for an ERP system. Work orders can be created within CADMAN-SDI for transfer to CADMAN-JOB.

Bulk creation of work orders with very limited manual inputs simplifies the “art” to “part” process. This functionality makes CADMAN a practical solution for sheet metalworking businesses of all sizes, including those who don’t have an ERP system.

IMPROVED GEOMETRY DETECTION

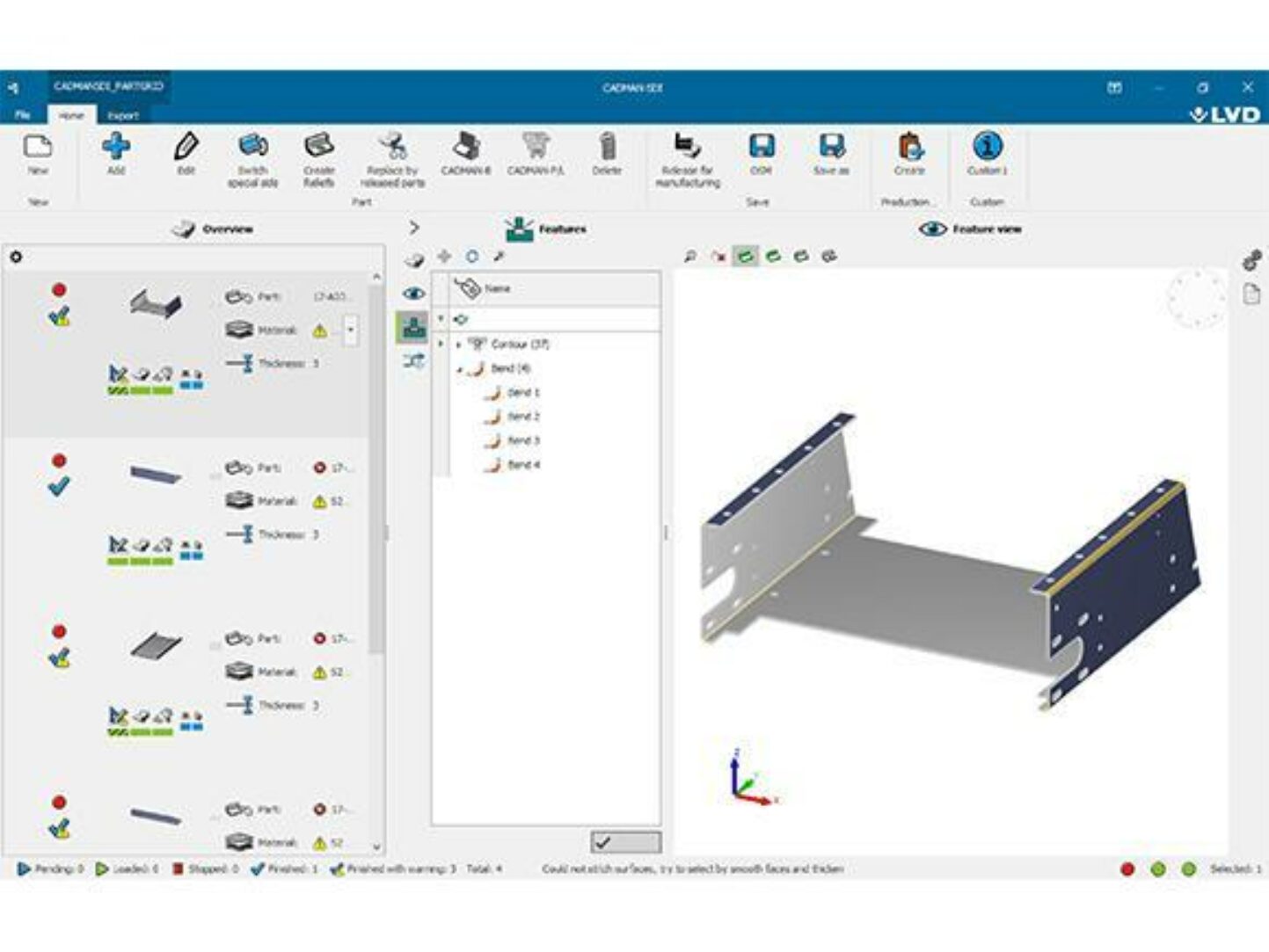

CADMAN-SDI receives a major update in v8.7 and is now able to detect foreign operations in the 3D geometry. For example, a hole with a diameter between 4.1 and 4.3 mm can be detected and defined as a tapped hole M5. This saves time and makes it easy for operators to be instructed on the 3D geometry. Also, operations that can’t be detected in the geometry, like grinding or painting, can be added in ERP or CADMAN-JOB when the work order is created.

With v8.7, CADMAN-SDI now offers a feasibility check. It checks for available machines and tooling, verifies the part geometry and warns of any problem geometries.

When holes are too close to the bend line and risk deformation after bending, CADMAN-SDI can automatically add a relief cut to the DXF file.

OPTIMISED PROCESS FLOW

CADMAN-JOB optimizes process flow by creating an execution plan based on the necessary operations and any constraints. For instance, some operations have hard constraints like laser cutting must come first, while other operations, like tapping, are possible before or after bending. CADMAN-JOB v8.7 also provides the flexibility of adding unplanned operations during production.

BETTER CAM SOLUTIONS

In addition, CADMAN-P and CADMAN-L now offer easy “drag and drop” importation of files. CADMAN-L can destroy internal contours using a spiral cut, avoiding possible collisions and saving processing time. The latest version of LVD’s punching and laser cutting CAM software maximizes material usage with the option to “expand parts.” When the sheet is not completely used but there is not enough material to create a remnant, CADMAN can automatically spread parts over the entire sheet, thus providing larger margins between parts for increased stability during cutting.

CADMAN v8.7 is available by contacting LVD software support at software.support@lvdgroup.com.