LVD Company nv highlights productivity solutions for smart manufacturing at EuroBLECH, Hall 12 – Stand F104. On display is 20 kW laser cutting, bending automation, folding and software technology, including a new low-cost fiber laser, high-tonnage Easy-Form press brake, Easy-Cell robotic bending cell, fully-automatic panel bender, and the latest in CADMAN® software.

Cost-Efficient 2D and Bevel Cutting

LVD will unveil a new laser cutting machine offering low investment and operating costs. An ultra-practical machine, it provides reliable cutting minus costly extra features. The new laser is available in three configurations to meet price/performance needs and thus deliver the lowest cost per part manufacturing. It can be equipped with a MOVit Load-Assist automation system.

LVD will demonstrate the diversity of its laser cutting technology using a LaserCube. This compact system will feature high-power 20 kW cutting, bevel cutting at a maximum bevel angle of 50 degrees, mixed gas cutting, and 19” Touch-L control. It will showcase smart cutting with optimized sheet utilization, nano joints, micro welding, remnant creation, collision avoidance.

Heavy-Duty Bending with Quality Assurance

The Easy-Form 9 400/40 press brake will be the largest, high-tonnage press brake LVD has ever exhibited at EuroBLECH. The 400-ton machine is floor mounted, no foundation required. It features a 6-axis modular backgauge for high application versatility and a total of 10 axis for precise bending of large and long parts. A built-in Easy-Form® Laser adaptive bending system guarantees repeatable accuracy for quality assurance.

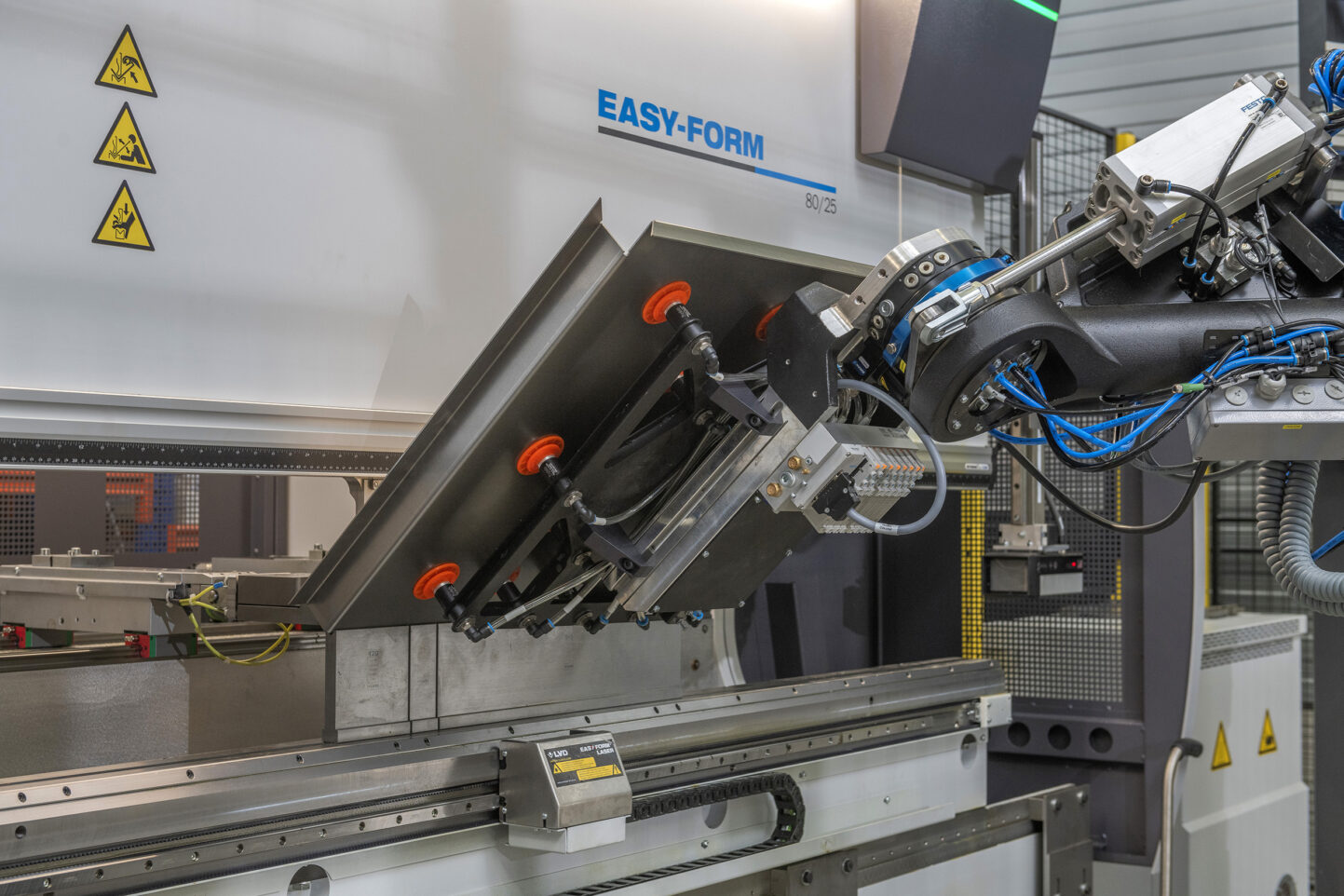

Highly Flexible Robotic Bending Cell

Easy-Cell 80/25 combines an Easy-Form 80-ton press brake with Kuka industrial robot to automate bending of parts from 100 x 100 mm up to 1600 x 1200 mm weighing up to 25 kg. The press brake features a 2500 mm bend length, five-axis backgauge, and 2500 mm crowning table, providing the flexibility to accommodate a wide scope of applications. Easy-Cell features an adaptive bending system which ensures bend angle accuracy from the first part. LVD CADMAN® software provides fast, simple offline programming of both press brake and robot.

Fully-Automatic Panel Bender

LVD’s Multifold 2111 panel bender will demonstrate fully automatic loading, folding, and stacking of workpieces up to a maximum bend length of 2100 mm in material thicknesses up to 2 mm cold rolled steel with bend heights up to 110 mm. A flexible and time-efficient alternative to die bending for many applications, Multifold requires only one set of tooling – a universal set of servo-operated up-and-down folding blades – to produce numerous profiles and various types of bends.

Software for Process Flow

The latest software releases will be demonstrated, including CADMAN®-FLOW. CADMAN-Flow introduces a new generation of CADMAN, offering improved process overview, smarter tool optimization, easy ERP connection, and faster, more efficient bend solutions. CADMAN-FLOW improves the speed and flexibility of the process flow from a 3D file to machine code to final product, offering significant gains in productivity.

About LVD

LVD is a leading manufacturer of sheet metalworking equipment, including laser cutting systems, punch presses, press brakes, automatic and semi-automatic panel benders, guillotine shears and automation systems, integrated to and supported by its CADMAN® software suite. LVD Industry 4.0-ready products and technology make smart manufacturing possible. For more information, visit: www.lvdgroup.com.