Prima Power, the world-class provider of sheet metal processing solutions, will exhibit its latest technologies at FABTECH, North America’s Largest Metal Forming, Fabricating, Welding, and Finishing Event.

Prima Power offers integrated automation solutions designed to meet customers’ current challenges and future growth, based on high-performance machines that deliver dynamic, precise execution. Prima Power can deliver stand-alone machines and equip them with different levels of automation at any stage of machine lifetime, or entirely automatic manufacturing lines as a turnkey solution. The solutions exhibited at FABTECH 2023 are parts of a full range of modular solutions, developed with a distinctive consulting approach and long-standing expertise in systems and machinery — all based on a unique history of technological integration.

LASER GENIUS+ WITH COMPACT SERVER AND PSR 2D

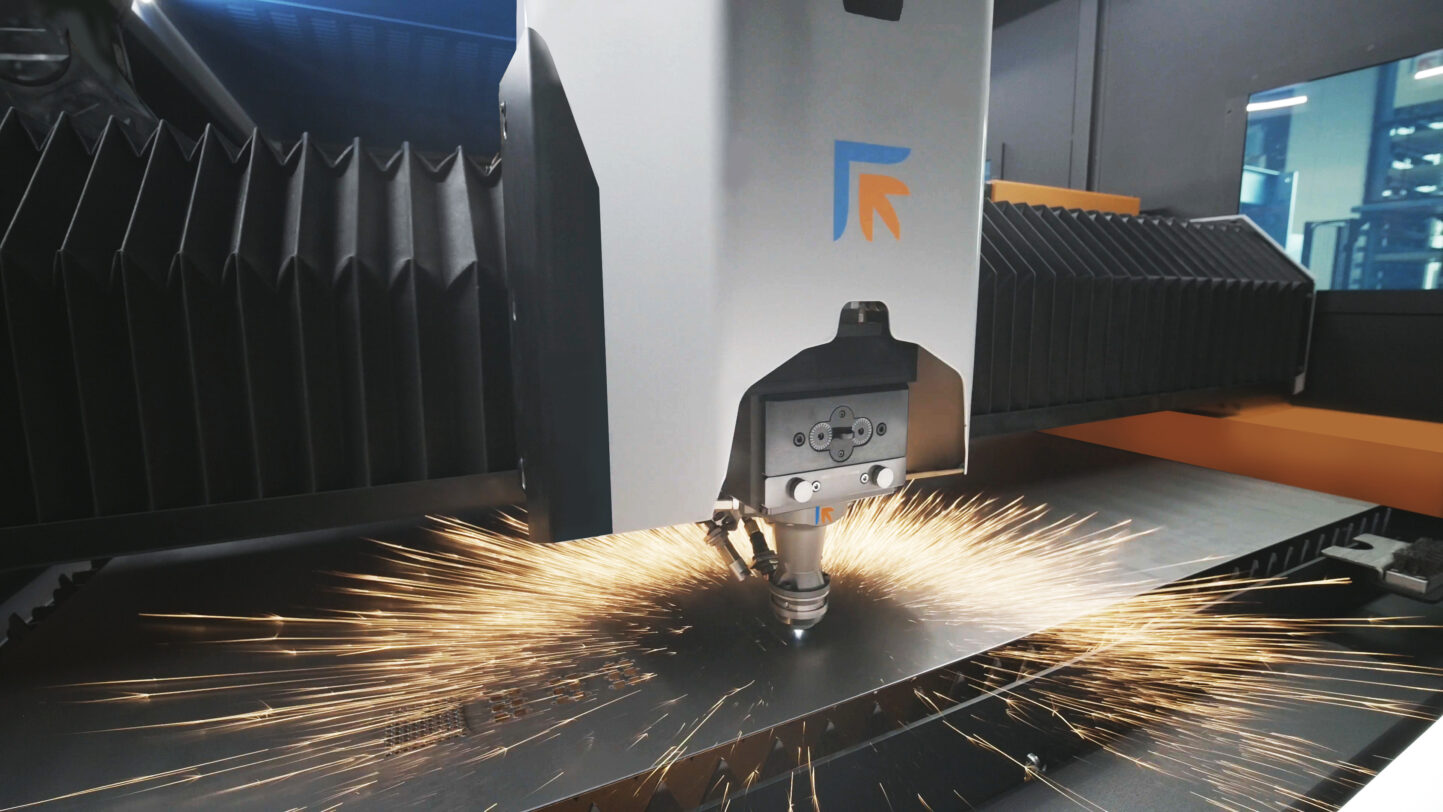

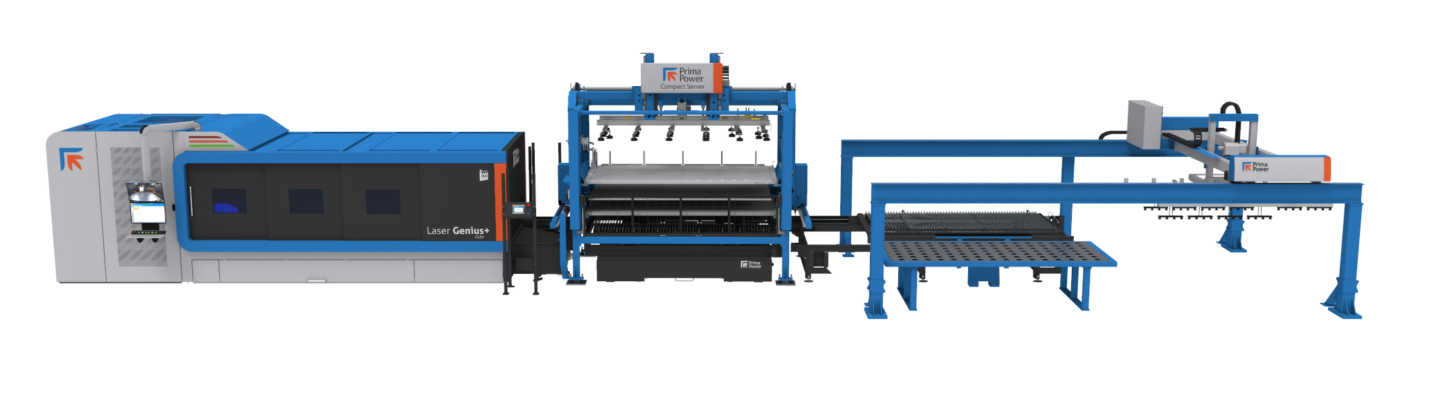

For flexible automatic laser cutting, Prima Power will display the Laser Genius+ with Compact Server automatic loading/ unloading device and PSR 2D picking and stacking robot.

The high dynamics (path speed of 180 m/min, acceleration of 2.8 g) and precision of Laser Genius + allow short cycle times and high cutting quality. It can meet any application’s needs with three sizes - 1530, 2040, and 2060 - and a wide range of laser powers.

Laser Genius+ is a “plug-and-play” machine with short installation times and a symmetrical and reversible layout that improves ergonomics and ease of integration into any production context.

Easy to use and smart, Laser Genius+ comes standard with two 24-inch full HD monitors and a 4K video camera, integrated software modules that simplify and optimize processes, new sensors and artificial intelligence algorithms for advanced monitoring and process control. Laser Genius+ can also be integrated with a full range of Prima Power automation solutions.

At FABTECH, the machine will be showcased with the 2-shelf Compact Server automatic loading and unloading device for both raw and processed sheets and an additional loading/unloading station.

This configuration also includes the PSR 2D, an intelligent and flexible picking and stacking robot that provides high stacking accuracy and minimal stack spacing, automatically optimizing the use of the stacking area.

Thanks to the modular structure of the system and Prima Power’s wide product portfolio, the PSR 2D can be directly connected to the Night Train FMS storage solution and an automatic panel bender, creating an automated production line from raw sheet metal to cut and bent finished parts.

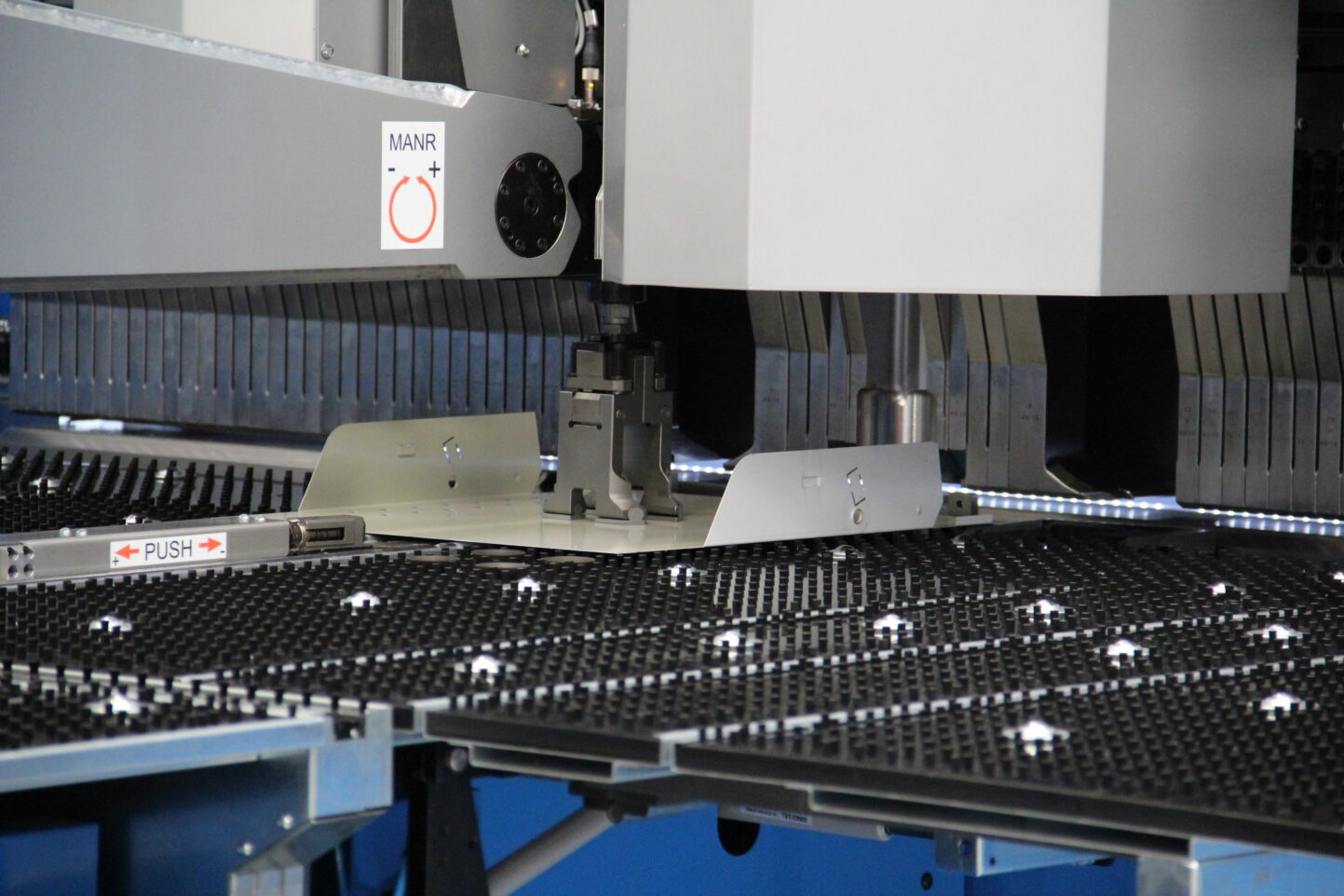

COMBI SHARP 1530 WITH COMPACT EXPRESS

At the Prima Power stand, visitors will also discover the advanced combi-laser machine Combi Sharp, featuring numerically controlled servo-electric axes, which provide outstanding energy efficiency, low maintenance requirements, and high execution speed. Its productivity is made possible by its large tooling capacity, a wide range of available special tools and quick and easy set-up changes.

With Combi Sharp, application flexibility is at its highest level: punching, forming, marking, bending, and laser cutting capabilities in one single manufacturing unit. By adding the Compact Express material loading and unloading device, the machine becomes an automated and efficient production cell with a very small footprint.

With this device, material can be loaded and unloaded during machine operation, but manual loading and unloading operations are also still possible, as one side of the machine is open for the operator. Combi Sharp is a very versatile, multifunction machine for very different sheet metal product manufacturing up to 8 mm thickness. With the Compact Express automation, several different materials can be stored for various products and production batches.

The combination of sustainability and profitability is also an important benefit of this machine: energy consumption reduction with servo-electric punching and Ecopunch technology (82% less compared to hydraulic solutions), less maintenance requirements, and the possibility to use cost-efficient compressed air as cutting gas.

The Prima Power Combi Sharp is ideal for job shops, where the variety of tasks, materials, and batch sizes is very high.

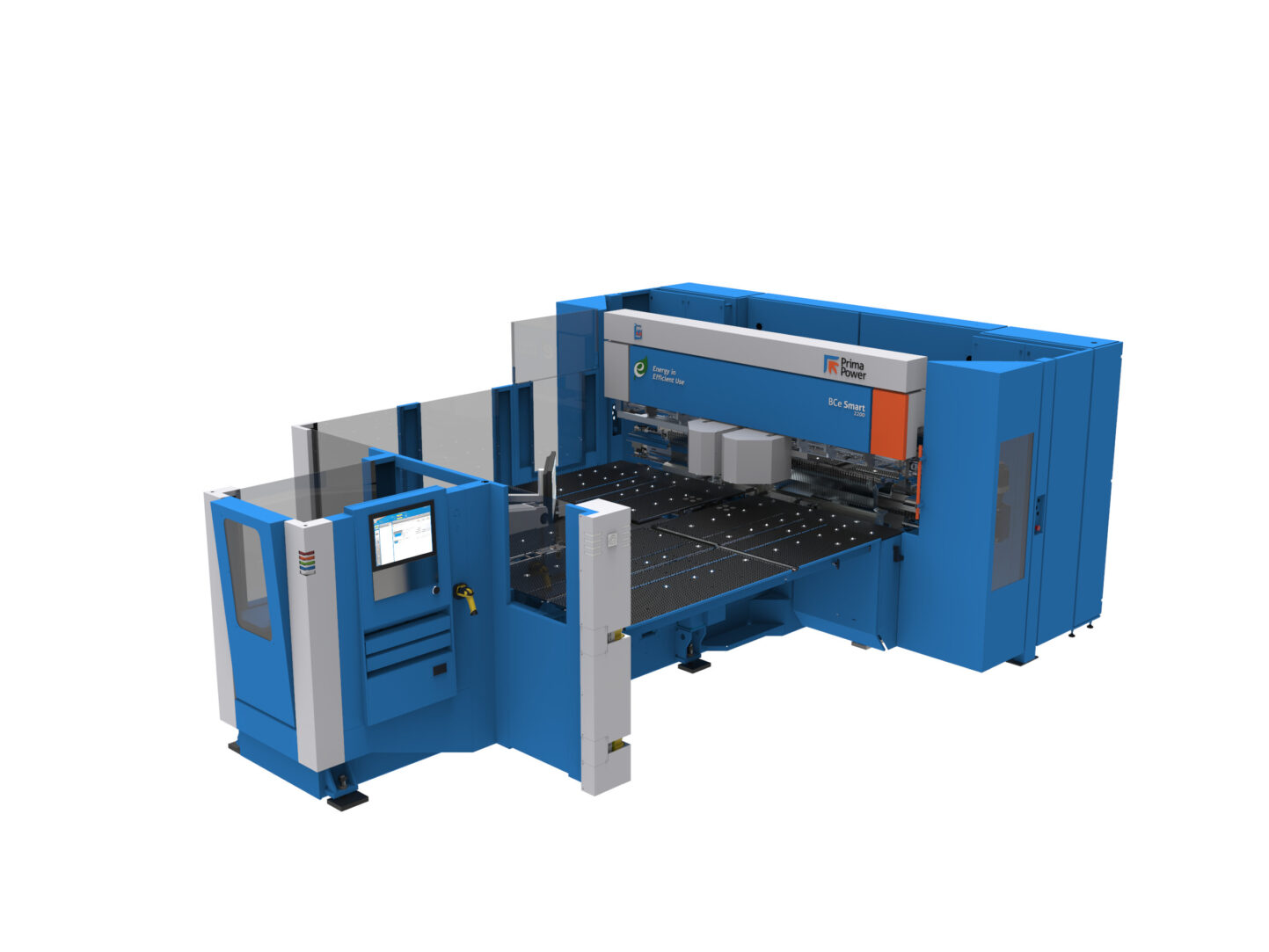

BCE SMART 2220

Also showcased at FABTECH, for bending applications, is the BCe Smart 2220, a semi-automatic panel bender featuring the highly-efficient servo-electric technology by Prima Power.

Reliable and efficient productivity is achieved through simultaneous loading and unloading. The operator loads the blank metal sheet and unloads the bent component in a single sequence while the machine automates all the bending cycles to guarantee an excellent bending quality thanks to its flexible bending capability.

Maximum ergonomics and safety are achieved thanks to two laser scanners, instead of physical barriers, and worktable tops that can be lowered to facilitate the loading of small or medium-sized parts.

The BCe Smart can be integrated with an industrial robot to reach higher levels of automation. With the robotized bending cell, the process can be fully automated, guaranteeing a higher repeatability of the product quality and a combination of productivity and flexibility. It features two operating modes, which can be selected according to production needs: semi-automatic, operated by the operator, when producing small batches, or fully automatic, served by the robot, when producing medium batches or when it is necessary to handle big parts.

This machine is the ideal solution for producing small and medium batches, as well as kit components and single parts, with an outstanding bending quality and a high repeatability.

At FABTECH Prima Power is showing all its software packages to support different levels of production automation. Prima Power software allows customers to manage their production in a fully integrated and interconnected way, with a significant increase in efficiency and productivity and a dramatic reduction in working times.