Prima Power will be the protagonist at the LAMIERA exhibition in Milan, the reference event for the sheet metal working machine tool industry, which will take place from 10 to 13 May.

For Prima Power this event will be an opportunity to present the most recent solutions and to discuss the latest trends in the sector with Italian and international visitors in a large stand designed, also from the point of view of hospitality, to make networking even more enjoyable and effective.

Under the spotlights of the Milan fair, Prima Power will exhibit two entirely Made in Italy products: a laser cutting solution and a bending one, produced respectively in the Collegno (TO) and Cologna Veneta (VR) plants. As always, the software will play a key role and it will be possible to request demonstrations and simulations of the digital ecosystem at the service of intelligent production at any time. The public at the fair will be able to discover, also through multimedia presentations, the entire range of technologies and automation solutions offered by the Prima Power brand to give more strength to the business of its customers.

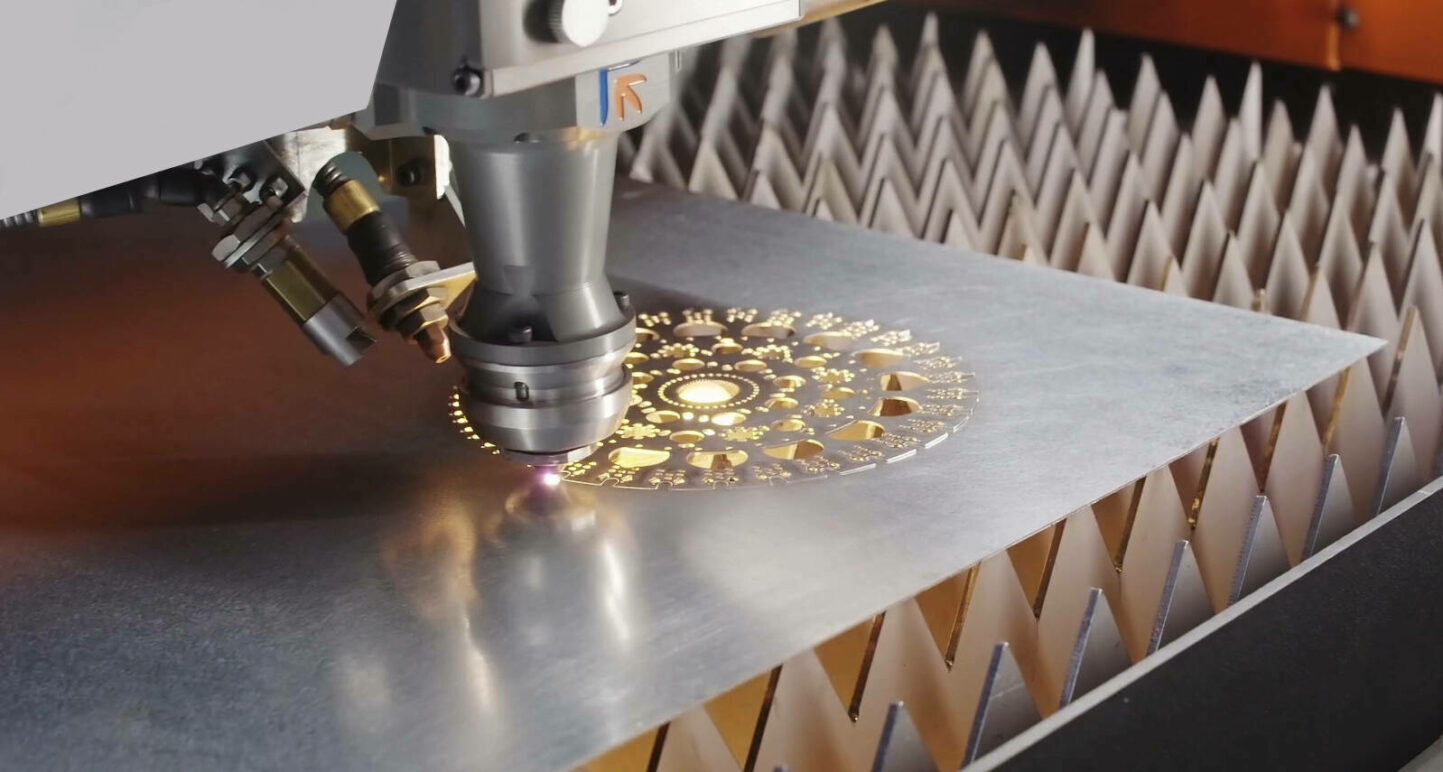

At LAMIERA it will be possible to get to know the Laser Genius+ machine with 15kW fiber laser, compact and efficient automatic material handling system Compact Server and Gas Mixer function, which enhances the versatility and effectiveness of the system. Laser Genius+, which stands out for its high productivity, application and configuration flexibility, and the complete range of automation and software functions, will be exhibited with a 15kW laser power, which allows a productivity increase of up to 53% compared to the 10kW source. The machine will also be equipped with Gas Mixer, the assist gas management system which allows for an improvement in cutting speed up to 15%, a reduction of residual burr by 50% on medium and high thicknesses and a reduction in operating costs.

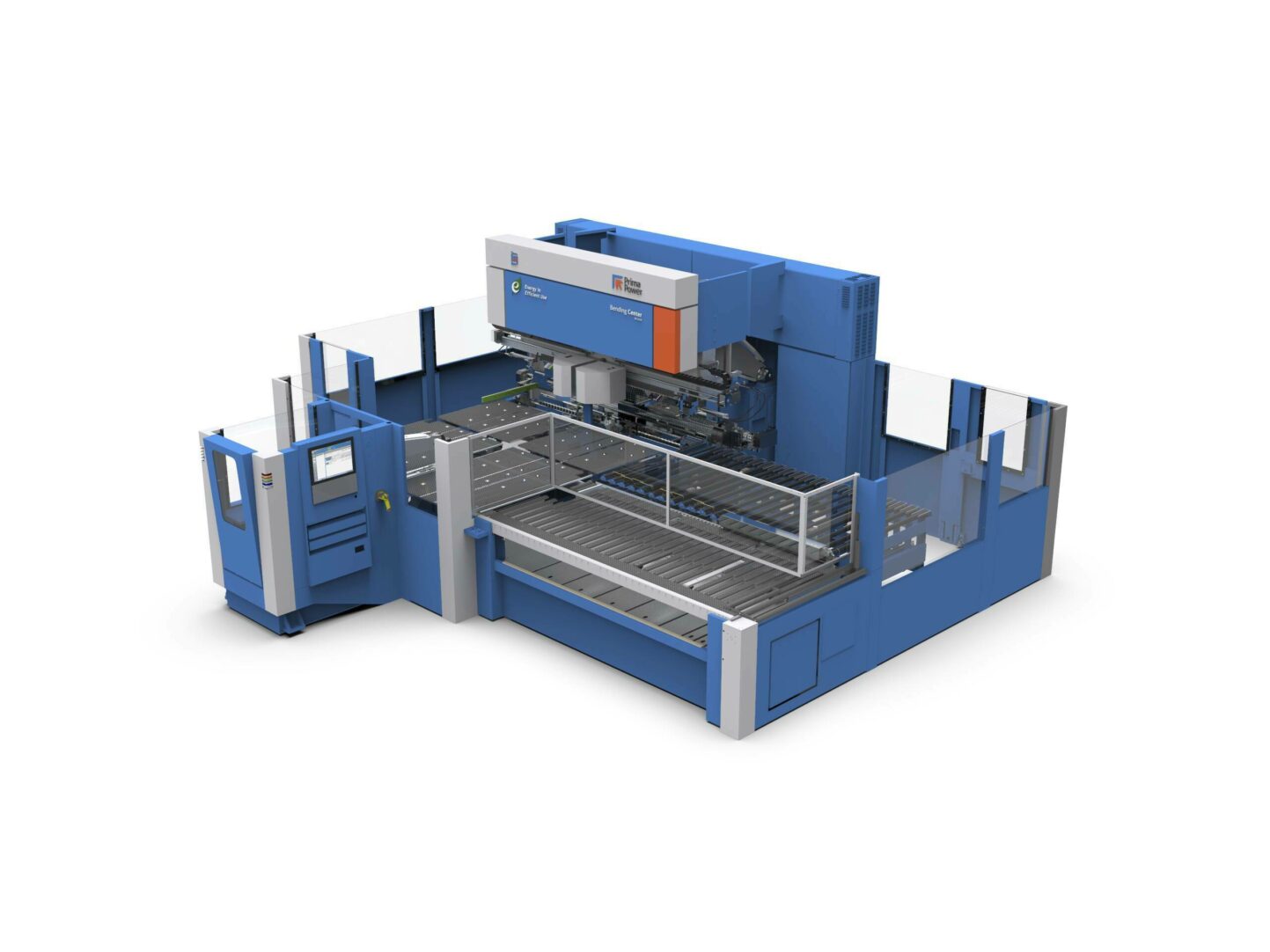

For bending technology, visitors will be able to see the Bending Center BCe 2720 semi-automatic panel bender at work. It is a servo-electric solution designed to achieve high productivity also thanks to the LUT loading and unloading table, which allows the operator to load a single sheet to be folded in masked time while the machine processes the previously loaded piece. Two safety laser scanners mounted on the LUT table, if interrupted, block the work cycle, protecting the user during all production phases. The BCe is the ideal solution for small to medium batches, including kits and fully perforated material. The machine can bend materials up to 2750 mm in length, with a bend height of 204 mm and can be equipped with options such as API angle correction which, combined with servo-electric technology, guarantees excellent bending quality, and the BCP device which allows the cutting and unloading of the bent profiles from the LUT table. The BCP option allows to bend profiles with the only panel bender that would otherwise require the use of a press brake, with an increase in productivity of over 15%.

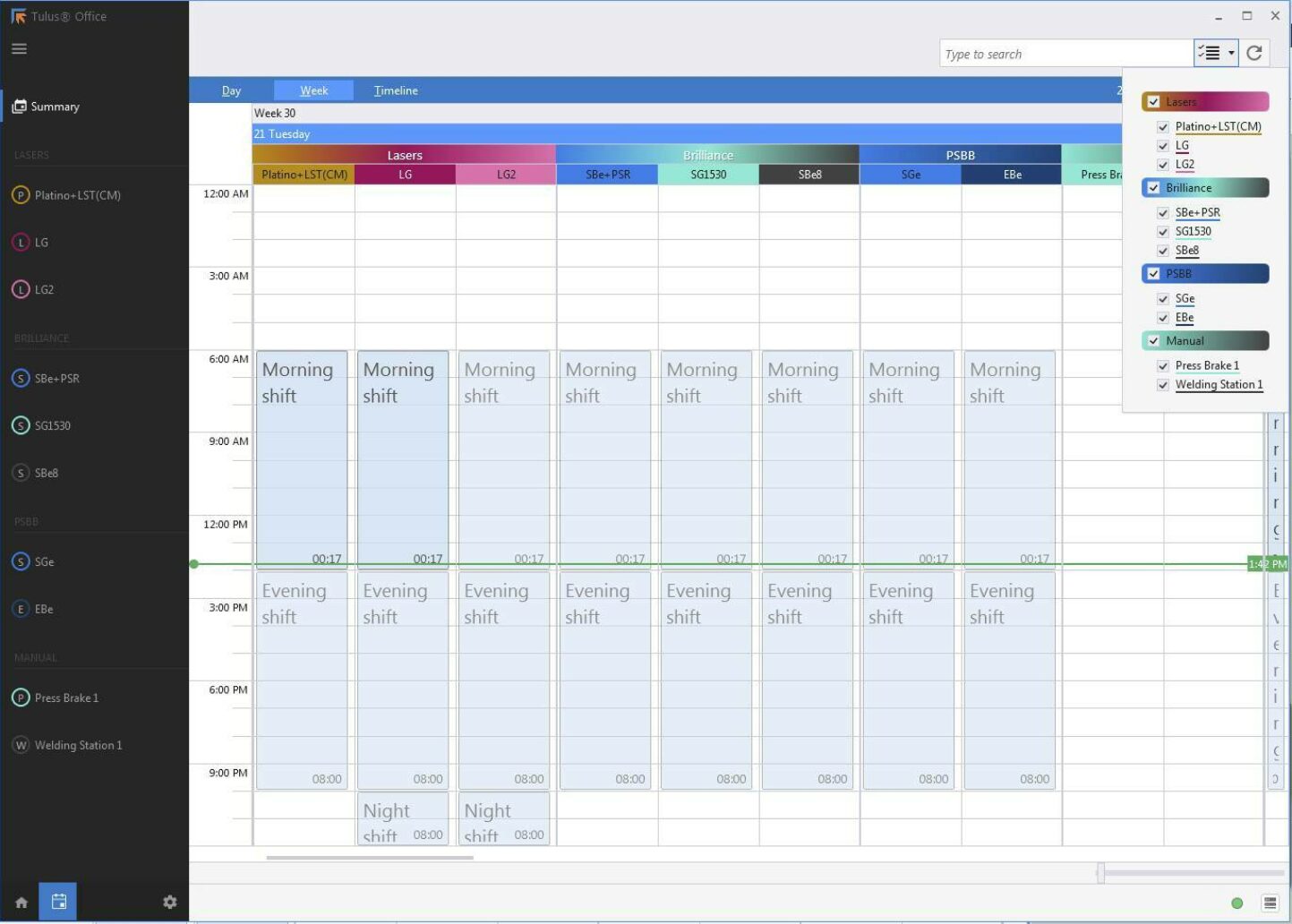

The software plays a strategic role in making production more efficient and in implementing digital and sustainable manufacturing, to create future-proof competitive advantages. The Prima Power software ecosystem offers solutions for each stage of production and Prima Power experts will be available to the LAMIERA public to illustrate the features and benefits of the various suites. Among these, Tulus Office, for production planning using a calendar that reduces the time it takes to put the piece into production; Remote Care, which accelerates diagnostic times and resolution of any machine alarms; NCExpress Parametric Programming, which maximizes speed and accuracy in the production of parts with slightly different dimensions or characteristics, allowing a single program to be used for several parts.

Prima Power's presence at Lamiera confirms its commitment to being close to customers with its experience and with efficient, smart, and flexible technological solutions, capable of responding to the needs of a constantly evolving market.