TRUMPF ToolMaster

TRUMPF ToolMaster boosts productivity by automatically switching between bending tools. The new generation ToolMaster can accommodate three times the tool metres as the previous model and changes a tool in just a few seconds. Users can insert both standard tools as well as ACB sensor tools and customer-specific special tools.

Visit the Showroom Enquire now

Simple setup

You can set up your bending machine automatically for each new program with the automatic ToolMaster tool change system. Modification to create the automated bending cell TruBend Cell 5000 is also possible. This represents a priceless benefit, particularly for small lot sizes, as you save a great deal of time and effort in comparison to the manual procedure.

Time spent searching and walking is now a thing of the past. While the ToolMaster changes your tools, you can take care of other tasks and benefit from user-friendly work processes. The precise positioning accuracy simplifies station operation for you.

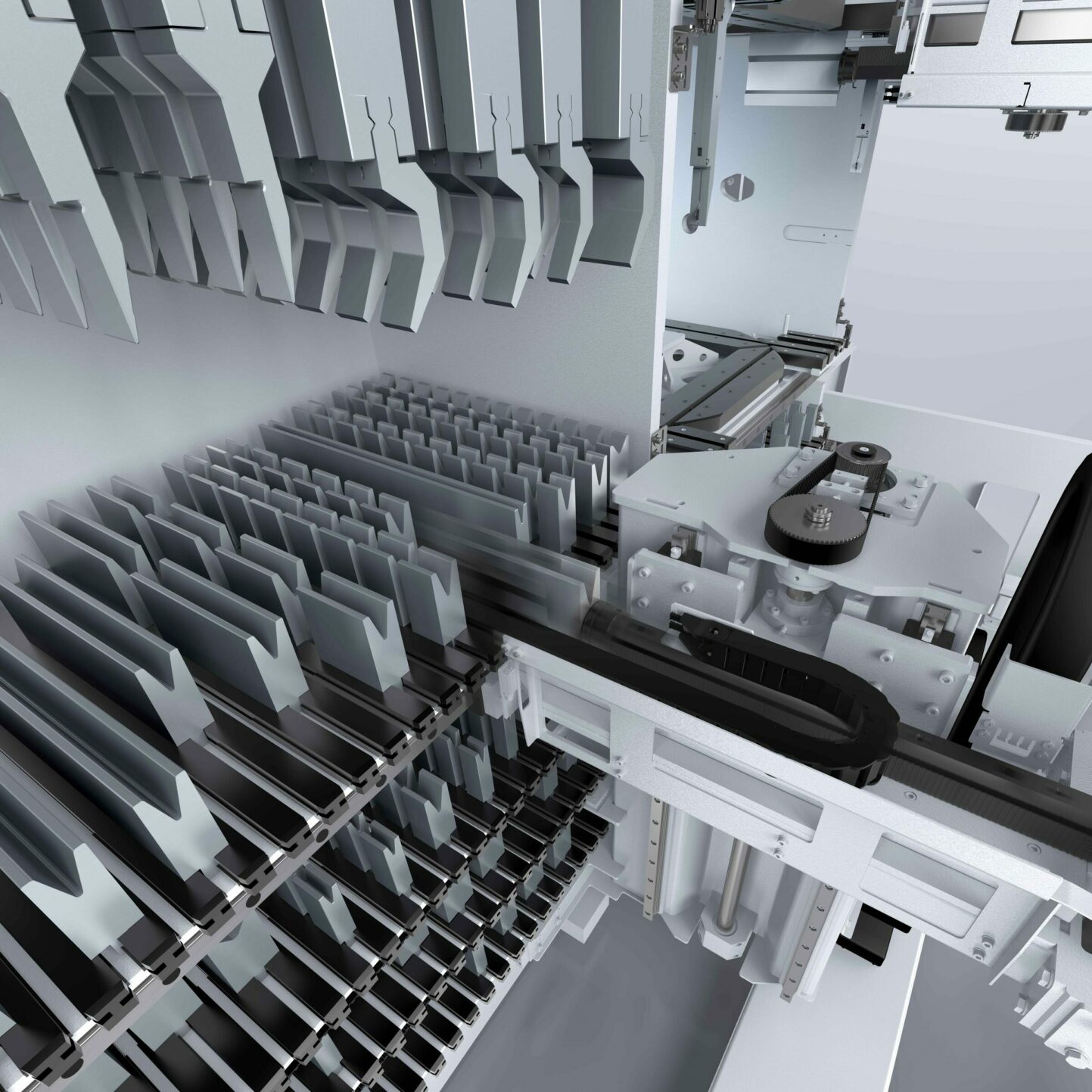

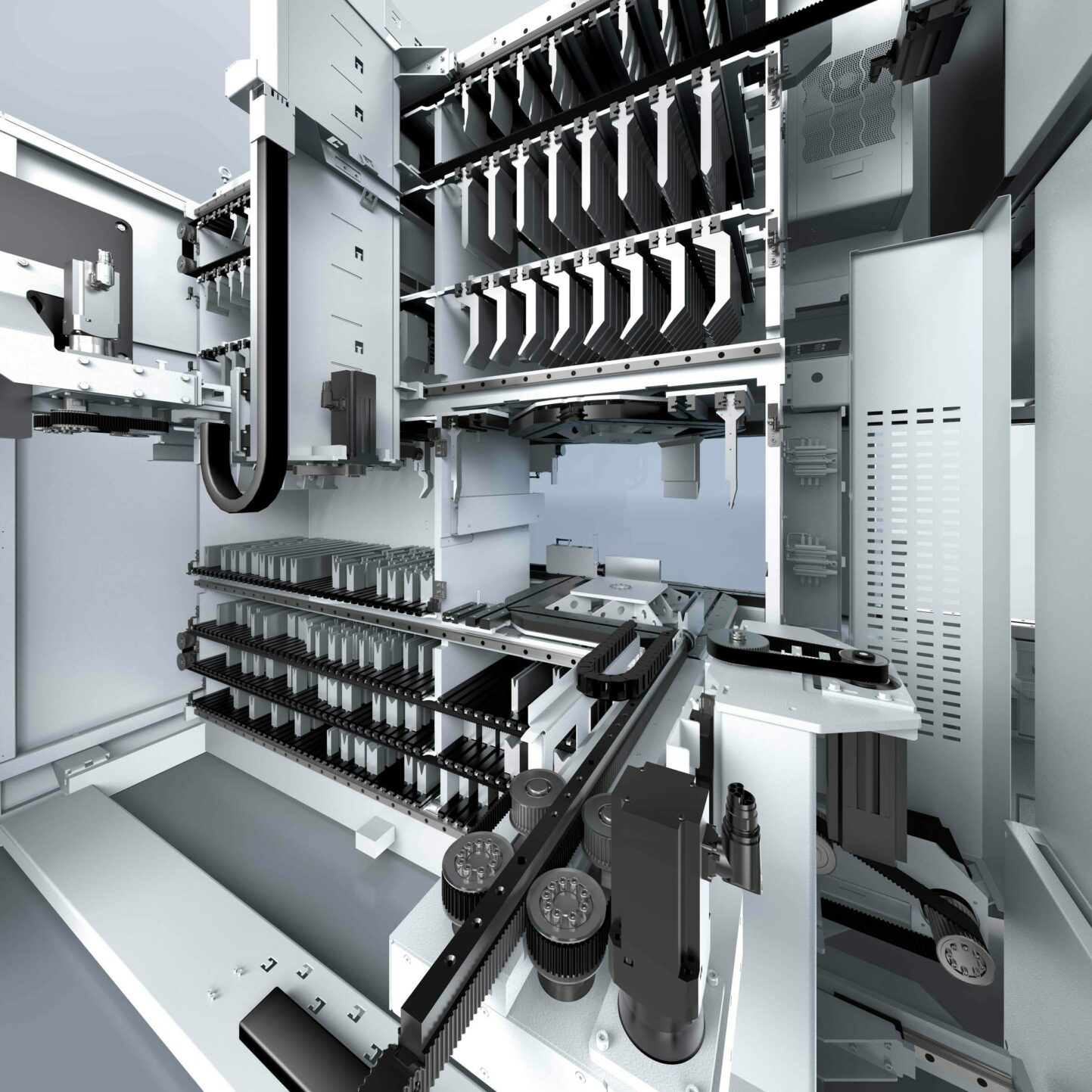

On the end of the tool cabinet, a multi-shelf racking system stores the punches and dies with a storage capacity of around 85 metres of tools (depending on the selected tooling) that are well protected against corrosion. TRUMPF has developed a unique three stage solution that achieves optimal efficiency for faster tool changes.

ToolMaster

In the first stage, there are two independent tool transfer arms - one for the punches and one for the dies. Each transfer arm comprises a multi-axis system that moves vertically and horizontally to access the multiple racks and shelves and a tool gripper that pulls the tools out from each shelf.

Once the tools are removed from the shelf, the transfer arms load the tools into two separate upper and lower turntables. Each turntable independently rotates 90 degrees, so that the tools are aligned with the press brake upper and lower tool holders. The upper turntable can also rotate in the opposite direction so that goose neck tools can be loaded in the inverted position.

In the final stage, two separate shuttles are used to load the punches and dies into position along the press brake.

Another interesting feature of the ToolMaster is the ability to easily load additional punches and dies into tool storage. The operator manually inserts the new tools into the upper and lower tool holders, then using a 2D hand-held scanner, scans the Data Matrix Code codes that are printed on the front of the tools. After scanning and confirming the entry at the machine control, the ToolMaster automatically transfers the tools to the storage cabinet.

| Tool Magazine Technical Data |

|---|

| Storage capacity, upper tools: 40m |

| Maximum upper tool height: 340mm |

| Storage capacity, lower tools: 44m |

| Maximum die width: Up to 120mm |

Contact TRUMPF

For more information visit www.trumpf.com.